Most Popular Products

Products

Automats Machine is used for bulk production of precision components for automobile, electrical and engineering fields. This multipurpose machine ensures higher profit at minimal investment. Mechanical bar stock feeding facility, accurate operation, low operating cost and long working life are the main characteristics of this machine.

This range of Bearing Race Grinders is reckoned for its high tolerance level. Low operating cost and low maintenance charge are some of the reasons of their huge demand in the market. High automation degree of these systems eliminates the necessity of continuous attention of operators.

This range of Bevel Gear Lappers is used for drilling job. Offered systems can maintain horizontal rotational direction. These can be installed vertically. Long working life, low maintenance design and reasonable price are the key aspects of such lappers.

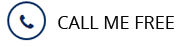

This array of Bevel Gear Testers has been developed by using cutting edge technical knowledge. Offered testing equipments belong to renowned brands like Stanko, Klingelnberg etc. Long working life and reasonable price are their unique features.

Driven by state of the art CNC mechanism, this Broach Sharpening Machine is preferred for its error free operation. Known for its stable performance, this machine decreases tool warping rate at the time of grinding. Its grinding speed is also higher than commonly used grinder.

In metal processing and precision machining arena, Broaching Machine is used to shape metal work pieces by adopting broaching method. This process is followed to attain specific shape of metal component by cutting both externally and internally. Generally, this machine is driven by mechanical or hydraulic power.

This range of CNC Lathe machines can be availed in different specifications. Utilization of advanced control panel, high speed, arrangement for installing new programs and low error are some of the unique features of these equipments.

Computer numerical control or CNC Machines are instrumental in regulating operation of various industrial equipments and tools. Every operating step of this machine is software programmed to guarantee about its flawless performance. Punch cards are used to input programs into these machines.

Die Casting Machine is used to develop automobile engine components and household electronic apparatus by using melted form of light alloy metal and molds. Developed as per global norms, this industrial equipment is energy efficient and it has high output level.

Drilling Machine is required to generate holes in specific work pieces by applying high force. This machine consists of movable spindle with manual or automatic mechanism, drilling head with multiple numbers of pulleys and work table for holding work piece tightly during drilling.

Forging Hammer is used to shape hardware accessories, automobile components, tableware items and hand tools by hammering. Featured with cast iron made structure, this hammer uses compressed air for its operation. The air pressure can be adjusted as per its application needs.

Gear Grinding Machines are used for producing worm gears, helical gears and spur gears to name a few. Pre programmed operation, high automation degree, graphics based menu displaying arrangement and mechanical inspection section are the main features of these machines.

Gear Rounding/Chamfering machine is preferred for its high performance level, application of electronic controller and standard quality. This machine is equipped with AC power driven variable speed motor, withdrawal facility of its chamfering head after completion of its automatic working cycle and vacuum dust collector.

Gear Shaping Machines have wide applications in ship designing, mining and wind power generation industries. These equipments consist of advanced guide rail with mechanical lubrication facility and electric temperature controlling arrangement. Servo motor drive and numerical control based mechanism ensure their precise functioning.

Featured with USB based user friendly file transferring interface, this Gear Shaving Machine is preferred for its compatibility with CNC router and other industrial machinery. Notable for its light beam structure, this equipment is preferred for its high output level, smooth operation, precise dimension and long working life.

Grinding Machines are used for improving surface quality of work pieces by using abrasive wheels. These equipments consist of guide equipped bed for proper positioning of metal object and abrasive wheel with high rotational speed. The coolants of these systems are useful to avoid overheating of work pieces.

Horizontal Boring Machine is used to enlarge existing holes in horizontal way. Available in floor or table mounted and other specifications based options, this boring equipment is driven by computer controlled mechanism. Ability to perform multiple cuts simultaneously, precise operation, high operating speed and user friendly design are its main attributes.

|

A. R. INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |